4.0 technology consists of technological solutions that aim to automate and connect industrial processes — cloud computing, artificial intelligence, Internet of Things (IoT), robotics, etc.

They are the result of the continued evolution of the industry over time.

Its biggest differential is process automation, so that machines can work without human interference.

In this respect, we cannot fail to talk about Industry 4.0, or the 4th Industrial Revolution, which is present in all areas of society; from smartphones to corporate robots.

Keep following to follow to understand better!

Want to know how Anatel Certification works? Here's how to get yours with the Master!

What is 4.0 technology?

Whenever we think of Industrial Revolution, we associate the term with steam machines and other concepts seen during school.

However, we have said above that technological innovations are evolving rapidly.

In this sense, it is worth stating that we are in the 4th Industrial Revolution, which is characterized by technologies with digital productions, artificial intelligence, automated robots and others.

Such technologies offer a great advance in the relationship between human beings and machines, with more efficient and information-based operations.

As a result, we see companies running more fluidly, saving costs and avoiding waste.

How did industry 4.0 technologies come about?

Like society, the evolution of the technologies that allowed us to reach Industry 4.0 was gradual. The advances went through historical stages, which began in Industry 1.0 through 4.0:

- Industry 1.0 (mechanical revolution): at the end of the 18th century, production modes were mechanized with the emergence of loom and steam machines. The first models appeared in textile factories, until reaching transport and agriculture;

- Industry 2.0 (electrical revolution): in the mid-16th century, discoveries came from new energy sources, in addition to steam, such as oil and hydroelectric plants. This generated an increase in production capacity;

- Industry 3.0 (automation times): in the 1970s, the development of computers, chips and software introduced automation to industrial productions. It was a period marked by information, with the arrival of man to the Moon and the Internet connection;

- Industry 4.0 (cyber era): since 2010, smart factories have emerged, providing more autonomy and virtualization of operations. Cloud computing and other advances have optimized the production process, making it more agile, efficient, and cost-effective.

What are the main objectives and characteristics of 4.0 technology?

Industry 4.0 and its main technologies have enabled numerous changes in the productivity of organizations.

As you've noticed in previous topics, your main goal is to make production processes leaner, more efficient, and more quality.

Check out its biggest features below.

Mass customization

This new industry offers technologies for flexible productions, with more accessible customization.

Traceability and Predictive Maintenance

They enable real-time monitoring of machines, devices and data. This makes it easier to detect failures and troubleshoot faster, and more accurate tracking.

Virtualization

Through sensors, cloud-stored information, and hyperconnectivity, processes can be managed remotely.

Decentralization

With the smartest machines, they can self-regulate as the market changes, leaving the human team free to perform strategic functions.

SaaS (Software as a Service)

With industry 4.0 technologies, software is offered as services instead of products.

They are also hosted in the cloud and billed on a recurring basis to ensure greater support for consumers.

Intercommunication

In the 4th Industrial Revolution, the machines are connected to each other and are able to communicate.

Leading industry technologies 4.0

Industry 4.0 enabling technologies have transformed society, forms of work, the functioning of industries and the environment in society.

Better understand what they are and their main characteristics.

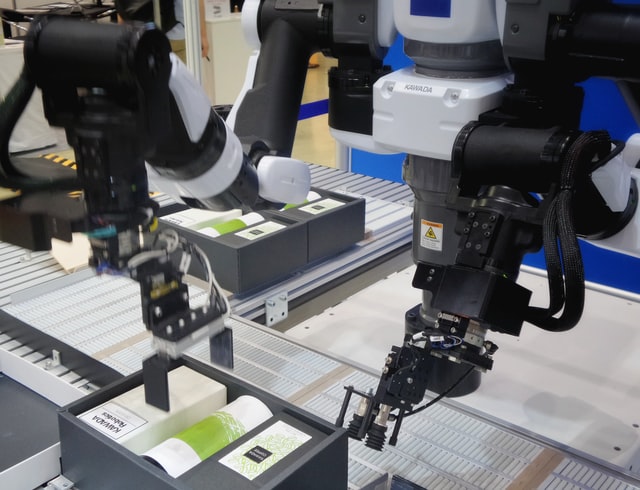

Collaborative robot

Also called Cobots, these machines operate together with professionals to unify workforces and give more automation to human capabilities.

Thus, employees stop performing repetitive and mechanically complicated tasks, and start to focus on tasks that require creativity, analytical thinking and common sense.

CPS (Cyber-Physical Systems)

These are systems responsible for digitizing business objects and physical processes, creating a kind of "digital twin".

This twin brother allows the realization of the processes with more dynamism; that is: when an order changes the software, the machine starts production with the changes automatically.

This system also serves to perform tests, simulations, control of failures and, consequently, prevent performance falls.

Additive manufacturing

Popularly known as 3D Printing, this type of fabrication consists of adding thin-layered materials to produce objects, from a bottom-up assembly.

This type of manufacturing makes it possible to create prototypes for a lower cost, less time, allows testing to be performed and thus avoid wasting resources in the industry.

Synthetic biology

It consists in the combination of technologies of the chemical, biological and genetic engineering industry, with the aim of contributing to the advances of medicine.

Synthetic biology allows the re-creation of existing biological systems, cell creation, enzymes, genetic circuits and others.

BPMS (Process Management System)

BPMS software is often used in organizations for business management. In practice, they use 4.0 technologies to optimize business performance.

In this system, the manager can map and model all the activities of the enterprise.

Thus, employees can more clearly visualize operations, from a cloud system, and act on them.

All changes are seen in real time, with information stored for future strategic comparations.

Thus, BPMS enables continuous business improvement, reducing costs and increasing the quality of deliveries.

Learn how to speed up the process of obtaining The Anatel Certification with Master!

Conclusion

4.0 technology is an inherent part of Industry 4.0. It is through new solutions that society can evolve and improve the quality of life of citizens.

Therefore, instead of fearing it, it is essential to study it to take advantage of its positive impacts.